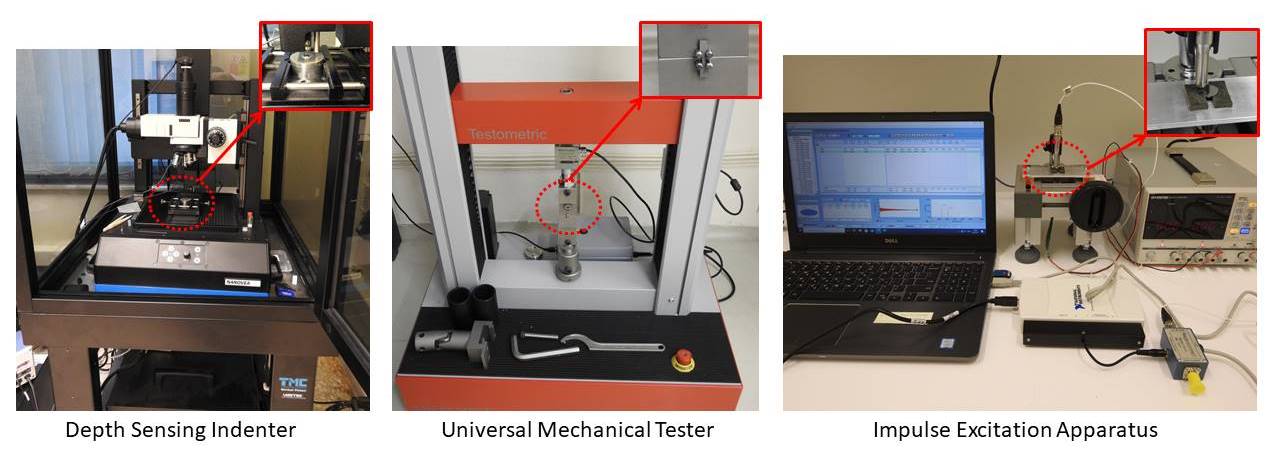

The Mechanical Testing infrastructure consists of the following apparatus for the measurement of the mechanical properties of materials.

Depth Sensing Nano/Micro-indenter

Equipped with

- Nano-module for nano-indentation (forces up to 600 mN)

- Micro-module for micro-indentation (forces up to 200 N)

- Motorised lateral (XY) 50mm×100mm movement witj lateral accuracy <2 µm

- Video zoom microscope, magnification up to ×100

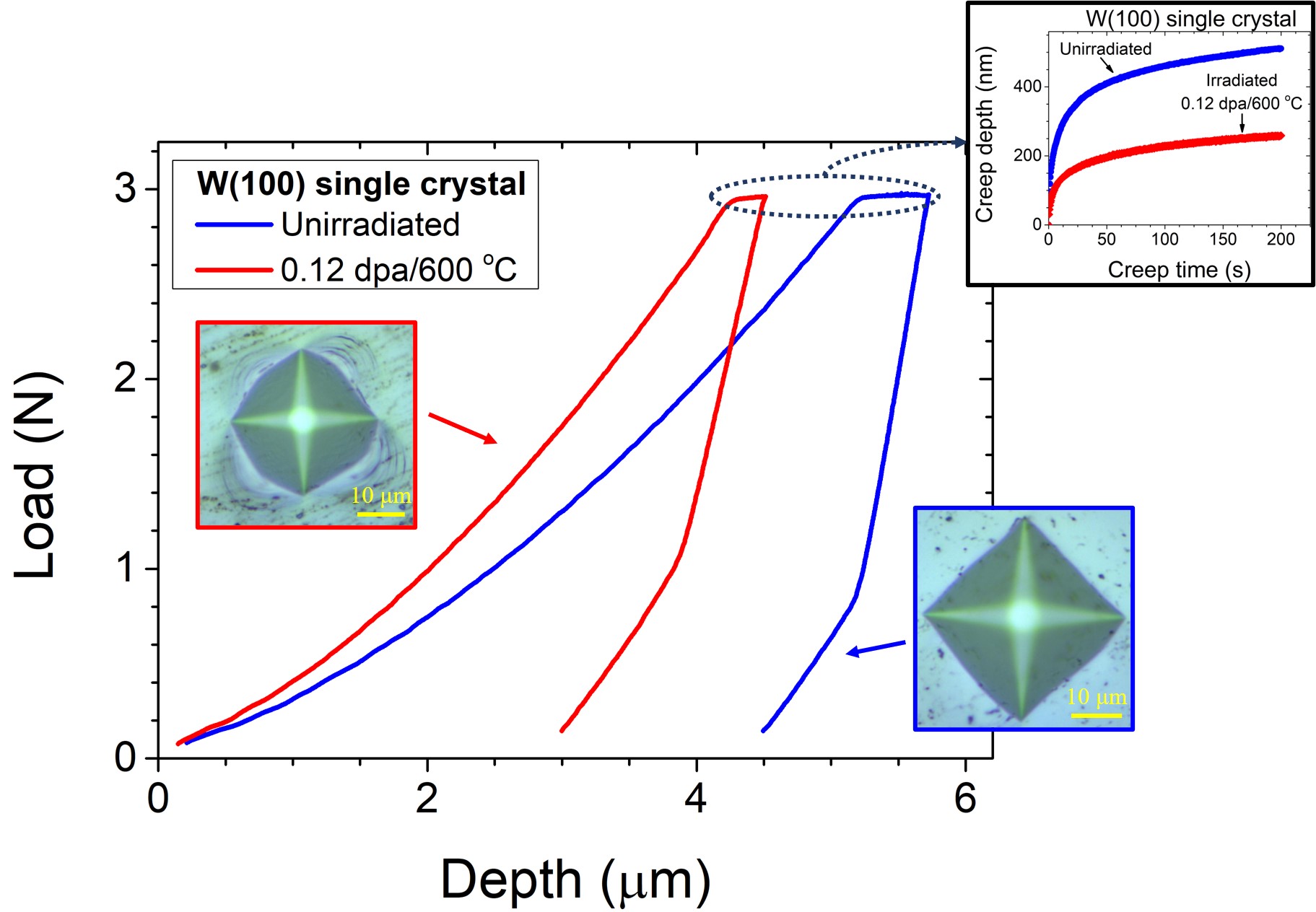

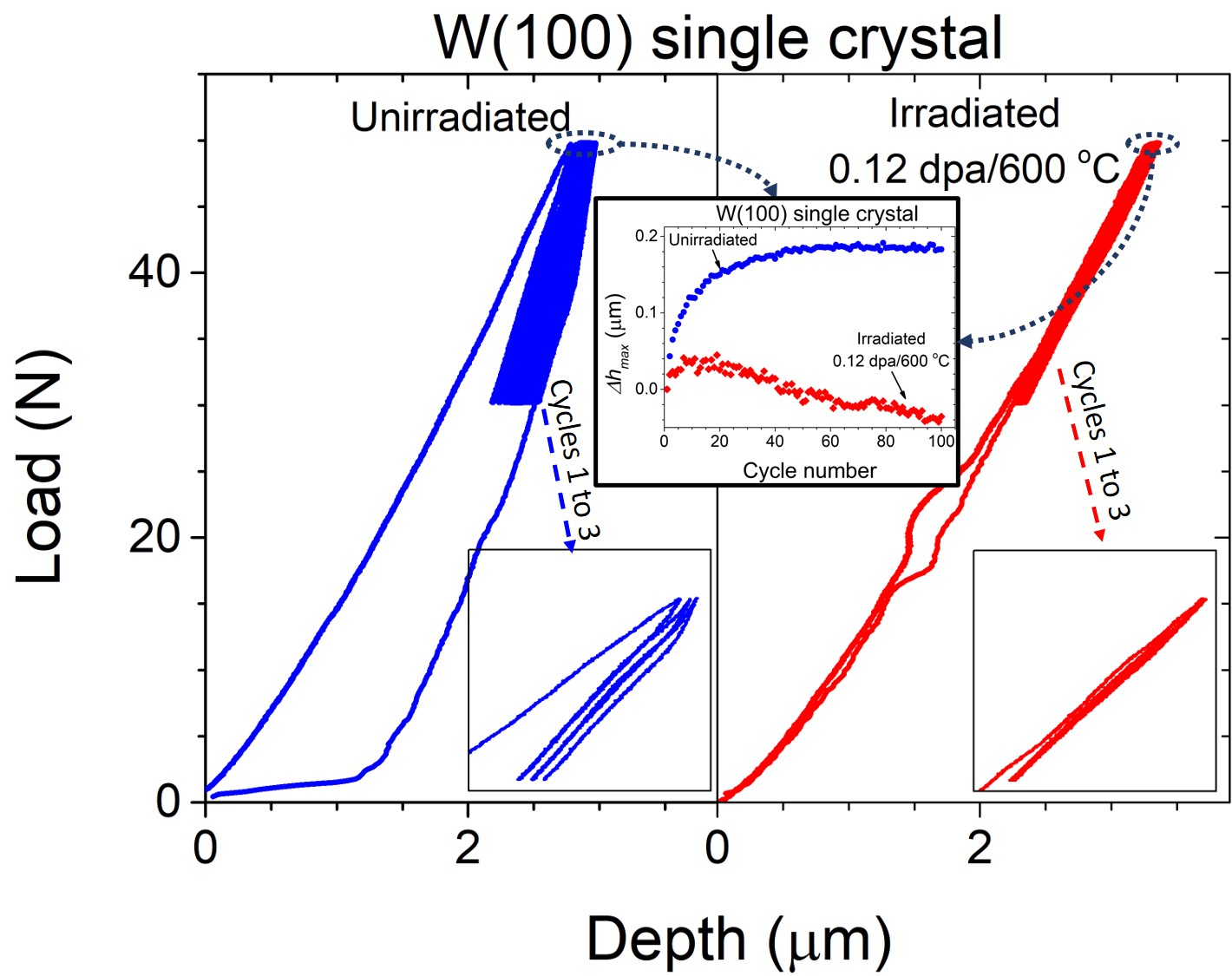

Mechanical properties of materials, such as hardness, stress strain curves, Young's modulus, yield strength, creep, fatigue and fracture toughness can be measured using indentation. During indentation, an indenter tip is driven into the sample by applying an increasing load up to a targeted value. The measured load is then gradually decreased until partial, or complete, relaxation of the sample has occurred. The load and displacement are recorded continuously throughout this process to produce a load-displacement curve. Adding a pause at maximum load allows studying of creep properties. The creep is measured by maintaining the applied force at a constant maximum value and measuring the change in depth of the indenter as a function of time.

Fig.1 shows an example of load–displacement curves for single crystal tungsten W(100) before and after neutron irradiation to 0.12 diplacements per atom (dpa) at 600 oC. From the initial part of the unloading curve the Young's modulus can be determined. The creep response of the material is measured by maintaining the applied force at a constant maximum value and measuring the change in depth of the indenter as a function of time (inset).

Fig.2 shows load-depth curves of multi-cycle micro-indentation measurements on tungsten W(100) single crystal before and after irradiation. Fatigue properties of the materials can be assessed through the evolution of the maximum and minimum penetration depth at each cycle (inset).

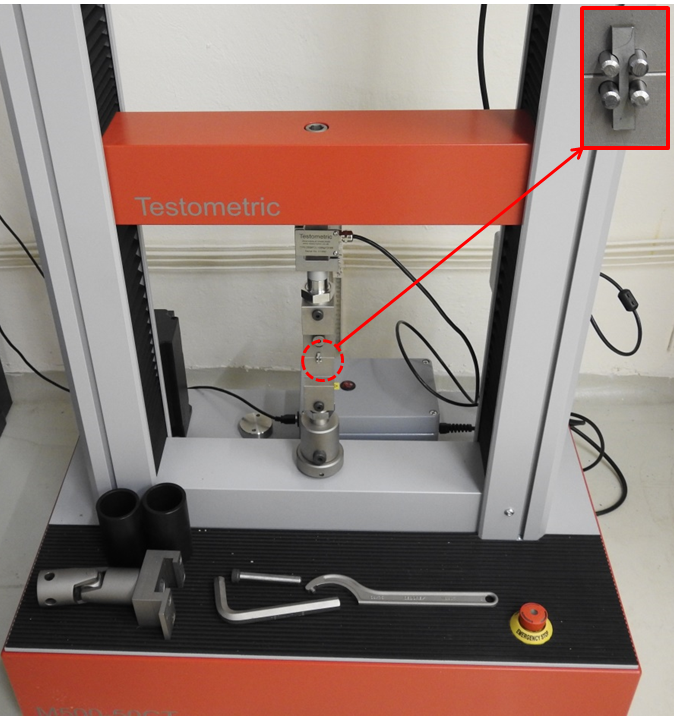

Universal Testing Machine

Equipped with

- High accuracy load cells of 10 and 50 kN maximum force in tension and compression

- Laser for displacement measurements up to 5 mm with readability 0.0001 mm and accuracy 0.2% of reading

for the measurement of

- Stress-Strain curves

- Pull-off tests

- Joint strengths

Impulse Excitation Apparatus

The Impulse Excitation Technique is a non-desctructive dynamic method for determining the elastic properties (Young's and shear moduli and Poisson ratio) of materials that are elastic, homogeneous and isotropic. The measurement principle is based on automatic tapping of the sample with a small projectile and recording the induced vibration signal with a microphone. The acquired vibration signal in the time domain is converted to the frequency domain by a fast Fourier transformation. Dedicated software determines the resonant frequency with high accuracy to calculate the elastic properties based on the classical beam theory.