Investigation of Plasma Facing Materials from the JET tokamak

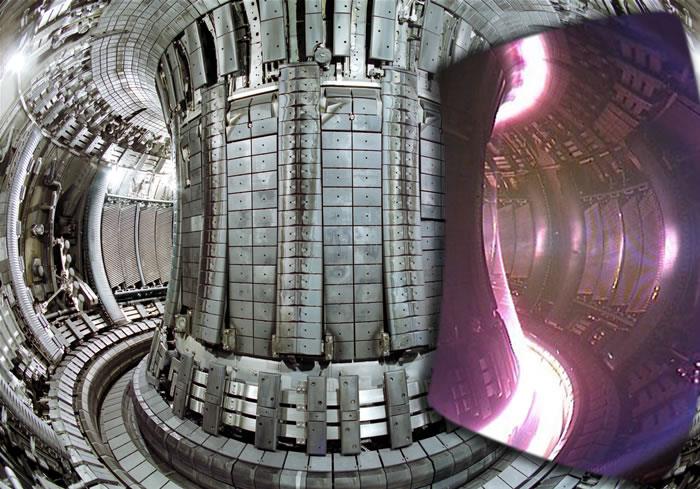

Erosion, deposition and materials migration in fusion plasma devices as well as fuel retention in plasma-facing components are issues of great importance for the safe operation of fusion devices. The underlying mechanisms of these phenomena require a good understanding in order to make predictions regarding the lifetime of wall components and to assess the amount of fuel retained in the machine. In 2010/11 the plasma facing components of the Joint European Torus (JET) were replaced by beryllium (Be) in the main chamber and tungsten (W) in the divertor, in order for JET to be used as a test bed for ITER since this material combination (Be and W) is foreseen for the activated phase of ITER.

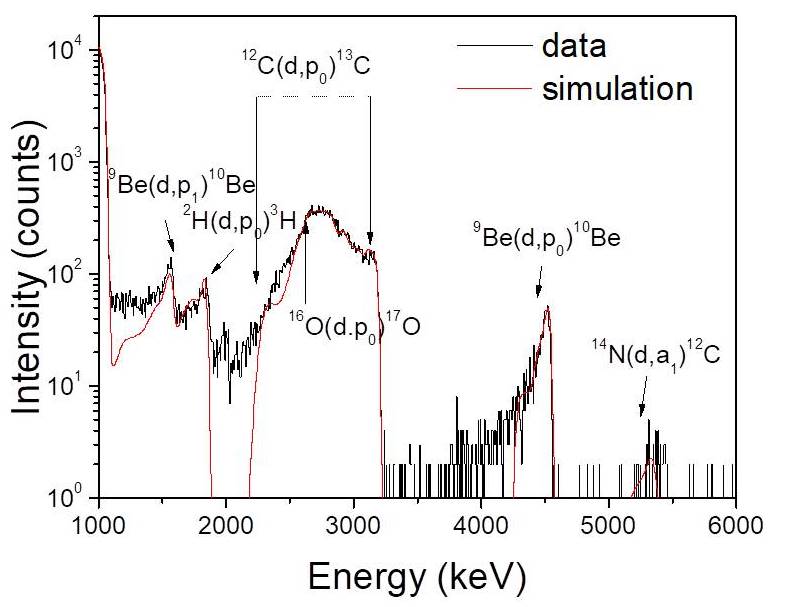

FTG members in collaboration with the TANDEM accelerator laboratory of the Institute of Nuclear and Particle Physics of NCSR “Demokritos”, investigate samples from different areas of the ITER-like wall of te JET tokamak consisting of beryllium and tungsten in order to assess material migration and deposition from other places of the tokamak wall and fuel retention, as well as erosion of the sample surface. Specimens are investigated using ion beam analysis, scanning electron microscopy (SEM) with energy dispersive analysis (EDS), X-ray fluorescence spectroscopy (XRF) and X-ray diffraction (XRD).

Neutron irradiation effects in tugsten materials

Tungsten (W) is the prime choice for armor materials for the divertor and first wall in current and future fusion devices due to its attractive properties such as high melting point, high thermal conductivity, low tritium retention, good sputtering resistance, thermal stress and shock resistance and low swelling under irradiation. However, it suffers from brittle behavior at low temperatures due ti its relatively high brittle to ductile transition temperature ranging from room temperature to several hundreds of degrees, and this causes a limitation of its exploitation.

Members of the FTG investigate neutron irradiation effects in different types of W materials such as the ITER grade, heavilly deformed and single crystalline tungsten. The neutron irradiations are performed at the BR2 reactor, in Belgium, in collaboration with SCK-CEN. Specifically the research activities refer to the mechanical properties and microstructural evolution as a function of the irradiation dose and temperature as well as the investigation of post-irradiation annealing effects on these properties.

The mechanical properties are determined using indentation and impulse excitation techniques, the open volume defects are assessed employing positron annihilation lifetime spectroscopy, and texture and microstresses are investigated using X-ray diffraction.